|

|

|

HOME > Field of business > Incinerator plant introduction HOME > Field of business > Incinerator plant introduction |

|

| |

|

| |

|

| |

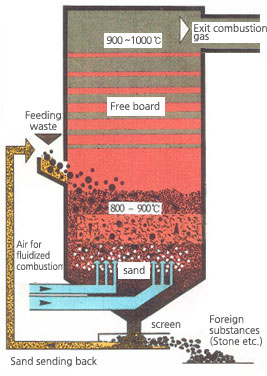

This is vertical cylindrical incinerator body with refractories in it, with sand as fluidization medium, into which continuous air of high pressure of 2,000~3,500mmAq is sprayed through nozzle. Sand is fluidized and forms fluidized-bed, and while sand maintains as high temperature of 900~1000℃, incineration designated waste is inserted, dried and incinerated instantaneously. The residue after incineration is discharged to the lower part with sand, among which only incineration residue is discharged segregated, and sand is inserted into the incinerator again to make the loss of sand minimized.

|

| |

|

| |

|

| |

| |

|

Suitable for flame retarding waste incineration, especially superior for incineration of sludge and waste oil, waste lubricating oil type. Suitable for flame retarding waste incineration, especially superior for incineration of sludge and waste oil, waste lubricating oil type.

Heat capacity of fluidized medium is big, so total destruction by fire and mixed firing of liquid, gaseous and solid waste is possible. Heat capacity of fluidized medium is big, so total destruction by fire and mixed firing of liquid, gaseous and solid waste is possible.

Reaction time is so fast, so incineration time is short. (Incinerator load factor high) Reaction time is so fast, so incineration time is short. (Incinerator load factor high)

Incineration efficiency high, unburnt matter discharge low, secondary combustion chamber not needed. Incineration efficiency high, unburnt matter discharge low, secondary combustion chamber not needed.

Gas temperature low, excess air amount low, NOx discharge low. Gas temperature low, excess air amount low, NOx discharge low.

Machinery driving part small, malfunction rate low. Machinery driving part small, malfunction rate low.

Incinerator temperature automatic control, so heat recovery easy. Incinerator temperature automatic control, so heat recovery easy.

Separation of residue from fluidized bed, not easy Separation of residue from fluidized bed, not easy

Shredding(pretreatment) is necessary for feeding waste or fluidization. Shredding(pretreatment) is necessary for feeding waste or fluidization.

Fluidized bed preparation and maintenance, and supplement are needed due to the loss of fluidized medium. Fluidized bed preparation and maintenance, and supplement are needed due to the loss of fluidized medium.

Operation cost, especially power cost, high. Operation cost, especially power cost, high.

|

| |

|

Municipal solid waste Municipal solid waste

Sludge Sludge

|

| |

|